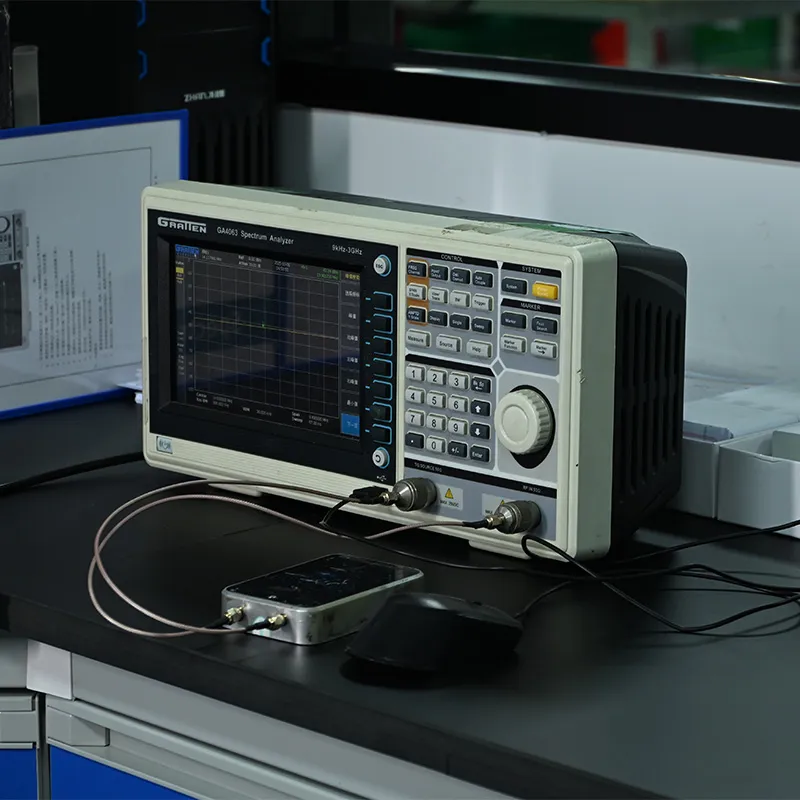

The RF Spectrum Analyzer enables fast and accurate RF measurements for RFID and smart-card systems, including carrier frequency, modulation quality, bandwidth, and spurious emissions. It supports performance verification, interference analysis, andcompliance testing of readers and tags.